| FindBook |

有 1 項符合

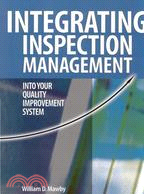

INTEGRATING INSPECTION MANAGEMENT的圖書 |

|

INTEGRATING INSPECTION MANAGEMENT 作者:WILLIAM D. MAWBY 出版社:ASQ 出版日期:2005-09-20 |

| 圖書館借閱 |

| 國家圖書館 | 全國圖書書目資訊網 | 國立公共資訊圖書館 | 電子書服務平台 | MetaCat 跨館整合查詢 |

| 臺北市立圖書館 | 新北市立圖書館 | 基隆市公共圖書館 | 桃園市立圖書館 | 新竹縣公共圖書館 |

| 苗栗縣立圖書館 | 臺中市立圖書館 | 彰化縣公共圖書館 | 南投縣文化局 | 雲林縣公共圖書館 |

| 嘉義縣圖書館 | 臺南市立圖書館 | 高雄市立圖書館 | 屏東縣公共圖書館 | 宜蘭縣公共圖書館 |

| 花蓮縣文化局 | 臺東縣文化處 |

|

|

- 圖書簡介

Though quality gurus have given it a bad name, the inspection of product and process has been a mainstay of quality programs since the inception of manufacturing processes. Inspection is becoming even more important today due to the deep computerization of processes, the wide availability of databases, and the need to reach ever-greater levels of quality. This book explains that the best continuous improvement programs are a blend of product and process efforts, and that the effective integration of them is the key to making rapid, economical advances in quality for the vast majority of manufacturing and services companies. Indeed, for many companies it is likely that the only way they are going to make the quality gains required without greatly exceeding their quality budgets is to effectively utilize their existing inspection systems.

Most modern quality programs still rely heavily on inspection systems, and therefore can be quickly and cost-effectively improved in the ways directed in this book. For example, the inspection system could utilize embedded sensors, relaying critical information back through the inspection process. This information can be filtered, integrated, and transformed into actions that can improve the quality of both product and process in a targeted fashion. Such a supercharged inspection system can be made a strong partner of your Six Sigma and lean manufacturing systems.

The concepts presented will be an advantage for any company, small or large, that wants to play in the high-quality ballpark but cannot afford the heavy, upfront expenditures that are often necessary in traditional approaches.

- 作者簡介

William D. Mawby has been with Michelin Tire Corporation for over 20 years and currently serves as manager for statistical and mathematical support for Michelin North America. Prior to this position, Mawby filled the role of chief statistician for Michelin Tire Corporation Research and Development Corporation in South Carolina. While there, he trained and consulted in SPC, DOE, reliability, multivariate methods, and other disciplines. Mawby holds a B.S. in natural systems from the Defiance College in Ohio and a Ph.D. in biomathematics from North Carolina State University.

|