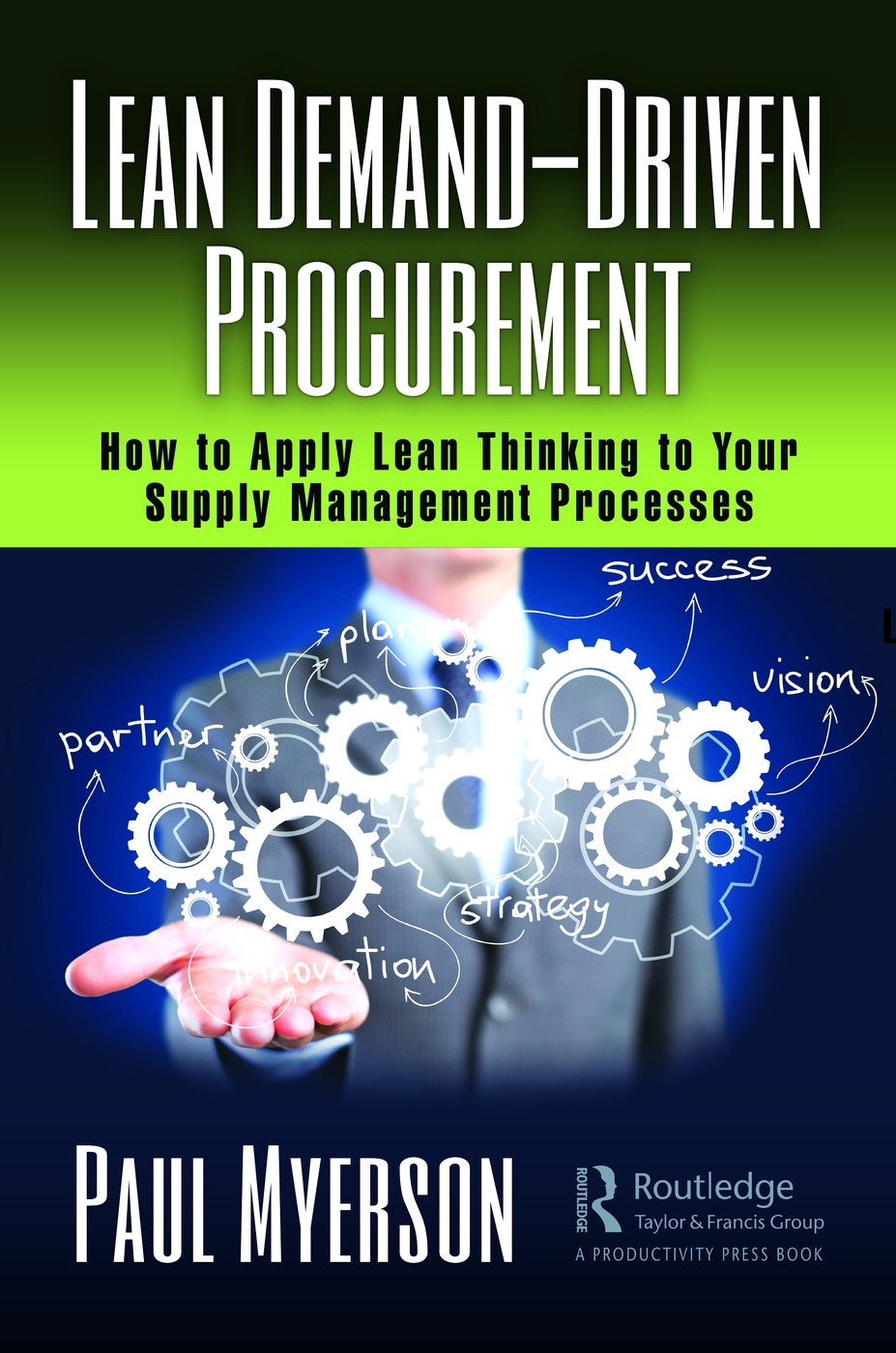

Lean thinking has expanded beyond its origins in repetitive manufacturing to other types of manufacturing processes such as process and product processes, and more recently to the administrative, supply chain, and operations management functions in a variety of industries.

While there are many books written on the basics of the "supply" side of the supply chain (i.e. strategic sourcing, sourcing/procurement and purchasing), however, there hasn’t been much written on those areas from a Lean perspective. Considering that supply chain costs, primarily procurement and transportation, can range from 50 to 70 percent of sales, it’s surprising that this area has not been fully explored. As a result, some companies tend to place too much emphasis on the traditional focus of reducing material costs instead of process improvement.

Applying Lean principles to procurement and purchasing processes identifies non-traditional sources of waste, and in some cases, creates a paradigm shift that results in additional benefits to the entire supply chain.

This book is unique because it details the basic supply management concepts and processes (i.e. sourcing, procurement, and purchasing) in an easy-to-understand format in combination with with various process improvement tools, methodologies, best practices, examples and cases written from a Lean perspective. It focuses and pinpoints ways to identify waste on the supply side through improved processes and, in some cases, technology.