Disassembly is one of the key elements of any processing of recovered products. Be it for repair, remanufacturing, refurbishing, cannibalisation, material recycling, or disposal. Hence, planning the disassembly is important and--with growing amounts of recovered products and need for saving resources--becomes even more important. The disassembly planning approaches presented are based on mathematical programming. With this methodology, a profit-optimal planning of quantities of multiple types of recovered products as well as parts distribution, material recycling, and disposal quantities is realised. Thereby, typical aspects, like material purity requirements, the condition of the recovered products, hazardous parts, and capacity limitations, are also considered. A new approach is the presented combination of disassembly-to-order planning and disassembly sequencing, which is called Flexible Disassembly Planning.

| FindBook |

有 1 項符合

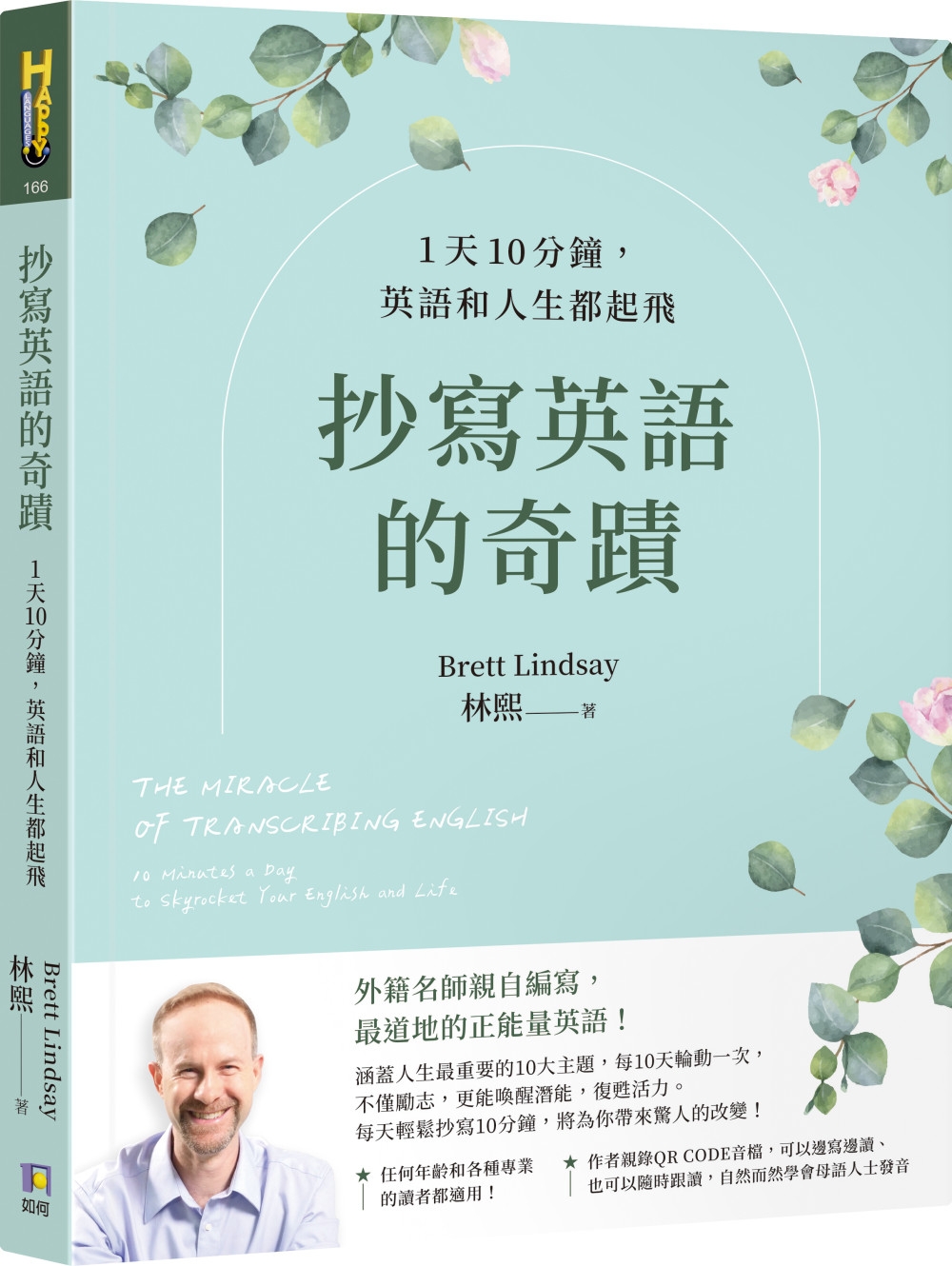

Advanced Disassembly Planning: Flexible, Price-Quantity Dependent, and Multi-Period Planning Approaches的圖書 |

|

Advanced Disassembly Planning: Flexible, Price-Quantity Dependent, and Multi-Period Planning Approaches 作者:Ullerich 出版社:Springer Gabler 出版日期:2013-07-25 語言:英文 規格:平裝 / 391頁 / 21.03 x 15.27 x 2.34 cm / 普通級/ 初版 |

| 圖書館借閱 |

| 國家圖書館 | 全國圖書書目資訊網 | 國立公共資訊圖書館 | 電子書服務平台 | MetaCat 跨館整合查詢 |

| 臺北市立圖書館 | 新北市立圖書館 | 基隆市公共圖書館 | 桃園市立圖書館 | 新竹縣公共圖書館 |

| 苗栗縣立圖書館 | 臺中市立圖書館 | 彰化縣公共圖書館 | 南投縣文化局 | 雲林縣公共圖書館 |

| 嘉義縣圖書館 | 臺南市立圖書館 | 高雄市立圖書館 | 屏東縣公共圖書館 | 宜蘭縣公共圖書館 |

| 花蓮縣文化局 | 臺東縣文化處 |

|

|

圖書介紹 - 資料來源:博客來 評分:

圖書名稱:Advanced Disassembly Planning: Flexible, Price-Quantity Dependent, and Multi-Period Planning Approaches

|