推薦序

前言(Preface)

CH1 緒論(Introduction)

1.1 前言 2

1.2 CAD/CAM 軟體技術與數控工具機暨高速加工 2

1.3 結語 9

1.4 參考文獻(References) 9

CH2 基本加工概念與切削條件(Basic concepts in machining and machining conditions)

2.1 基本加工概念( Basic concepts) 12

2.2 切削條件(Machining conditions) 30

CH3 PowerMILL® 使用入門(Getting started with PowerMILL®)

3.1 簡介(Introduction) 46

3.2 啟動PowerMILL® 46

3.3 PowerMILL® 使用入門 50

CH4 2.5D 銑削與鑽孔加工(2.5D milling and drilling)

4.1 簡介(Introduction) 72

4.2 基本設定(Basic set-up) 72

4.3 2D 平面加工(2D plane machining) 76

4.4 2.5D 粗加工(2.5D rough machining) 78

4.5 2.5D 精加工(2.5D finish machining) 82

4.6 倒斜角加工(Chamfer machining) 85

4.7 鑽孔加工(Drilling) 88

4.8 實體模擬加工(View mill simulation) 92

CH5 三軸銑削加工實習:瓶胚模(3 axis milling practice: preform mold)

5.1 簡介(Introduction) 96

5.2 基本設定(Basic set-up) 96

5.3 模型粗加工(Model rough machining) 102

5.4 點投影中加工(Projection point semi machining) 104

5.5 點投影精加工(Projection point finish machining) 108

5.6 NC 程式輸出(Output NC program) 113

CH6 三軸銑削加工實習:弓形模(3D milling practice: arcuate mold)

6.1 簡介(Introduction) 118

6.2 基本設定(Basic set-up) 118

6.3 模型粗加工(Model rough machining) 127

6.4 平面精加工(Plane finish machining) 133

6.5 曲面側銑中加工(Swarf semi machining) 135

6.6 曲面側銑精加工(Swarf finish machining) 143

6.7 3D 等距加工(3D offset machining) 148

6.8 鑽孔加工( Drill machining) 155

6.9 實體模擬加工(Simulation) 161

CH7 三軸銑削加工實習:管形模(3D milling practice: tubular mold)

7.1 簡介( Introduction) 164

7.2 基本設定( Basic set-up) 164

7.3 模型粗加工(Model rough machining) 173

7.4 模型餘料加工( Model rest machining) 178

7.5 最佳化等高中加工(Optimised constant Z semi machining) 183

7.6 最佳化等高精加工(Optimised constant Z finish machining) 187

CH8 三軸銑削加工實習:沖壓模(3D milling practice: stamping die)

8.1 簡介(Introduction) 194

8.2 基本設定(Basic set-up) 194

8.3 模型粗加工(Model rough machining) 202

8.4 模型餘料加工(Model rest machining) 206

8.5 平面精加工(Plane finish machining) 210

8.6 等高中精加工(Constant Z finishing) 214

8.7 曲面法向加工(Surface finishing) 223

8.8 沿面清角加工(Corner finishing) 226

8.9 電極加工應用(Electrode machining) 229

CH9 三軸銑削加工實習:相機模(3D milling practice: camera mold)

9.1 簡介(Introduction) 234

9.2 基本設定(Basic set-up) 234

9.3 模型粗加工(Model rough machining) 241

9.4 平面精加工(Plane finish machining) 243

9.5 最佳化等高精加工(Optimised constant Z finishing) 246

9.6 平行投影精加工(Raster finishing) 256

9.7 曲面法向精加工(Surface finishing) 260

9.8 曲面側銑精加工(Swarf finishing) 265

9.9 等高清角加工(Constant Z finishing) 270

CH10 三軸銑削加工實習:倒勾結構件(3D milling practice: overhanging structure)

10.1 簡介(Introduction) 276

10.2 基本設定(Basic set-up) 276

10.3 模型粗加工(Model rough machining) 287

10.4 等高中加工(Constant Z semi machining) 289

10.5 線投影中加工(Projection line semi machining) 293

10.6 線投影細加工(Projection line finish machining) 296

CH11 三軸銑削加工實習:賓士模(3D milling practice: mercedes mold)

11.1 簡介(Introduction) 302

11.2 基本設定(Basic set-up) 302

11.3 模型粗加工(Model rough machining) 307

11.4 模型餘料加工(Model rest machining) 310

11.5 模型二次餘料加工(Model rest machining once more) 316

11.6 平面精加工(Plane finish machining) 322

11.7 陡峭與淺灘中加工(Steep and shallow semi) 327

11.8 最佳化等高精加工(Optimised constant Z finishing) 335

11.9 自動清角加工(Corner finishing) 339

11.10 平行投影精加工(Raster finishing) 342

CH12 三軸銑削加工實習:吹風機模(3D milling practice: mold for hair dryer)

12.1 簡介(Introduction) 348

12.2 基本設定(Basic set-up) 348

12.3 模型粗加工(Model rough machining) 352

12.4 平面精加工(Plane finish machining) 355

12.5 模型餘料加工(Model rest machining) 358

12.6 模型二次餘料加工(Model rest machining once more) 361

12.7 最佳化等高中加工(Optimised constant Z finishing) 365

12.8 曲面法向精加工(Surface finishing) 371

12.9 自動清角加工(Corner finishing) 375

12.10 沿面投影精加工(Projection surface finishing) 377

12.11 曲面側銑溝槽加工(Swarf finishing) 386

CH13 三軸銑削加工實習:吸塵器模(3D milling practice: mold of vacuum cleaner)

13.1 簡介(Introduction) 392

13.2 基本設定(Basic set-up) 392

13.3 模型粗加工(Model rough machining) 393

13.4 平面精加工(Plane finish machining) 395

13.5 模型餘料加工(Model rest machining) 397

13.6 模型二次餘料加工(Model rest machining once more) 398

13.7 等高中精加工(Constant Z semi/Finish machining) 405

13.8 平行投影中精加工(Raster semi/Finish machining) 408

13.9 最佳化等高中精加工(Optimised constant Z semi/Finishing) 412

13.10 自動清角加工(Corner finishing) 418

CH14 路徑安全驗證及實體模擬(Tool-path safety confirmation and simulation)

14.1 路徑安全驗證 422

14.2 操作一 422

14.3 操作二 425

14.4 操作三 432

14.5 操作四 433

CH15 加工基本設定及運行(Basic setup and start machine)

15.1 CNC 銑床機體介紹 438

15.2 操作箱介紹 440

15.3 操作說明 454

附錄A G&M 碼基本機能簡介(Appendix A: introduction for basic G&M code)

附錄B 三軸銑削加工認證試題(Appendix B: certification for three-axis machining test)

| FindBook |

有 8 項符合

進階三軸銑削數控加工及實習的圖書 |

|

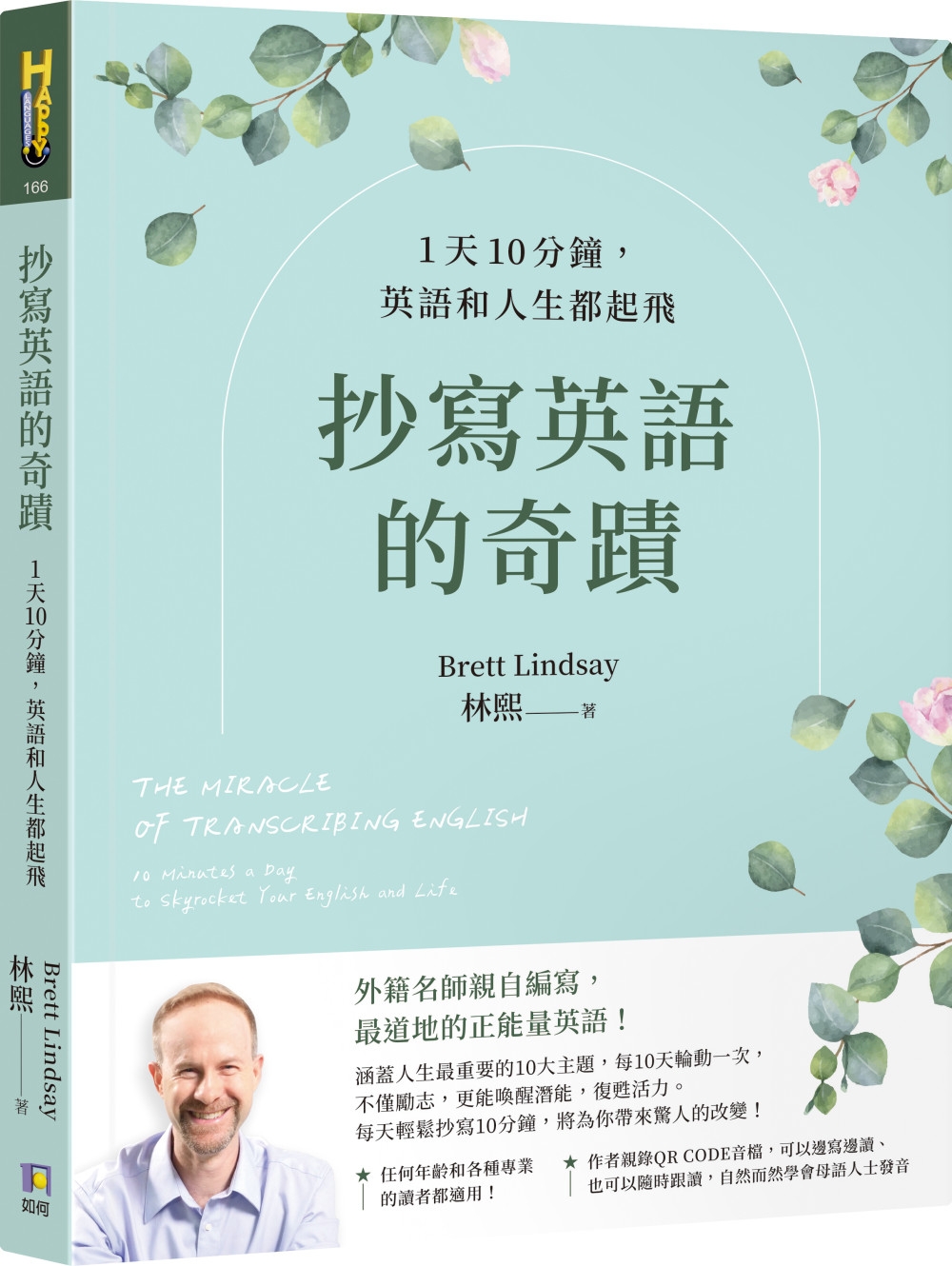

進階三軸銑削數控加工及實習 (第2版/附教學範例檔) 作者:吳世雄/王敬期/王松浩 出版社:五南圖書出版股份有限公司 出版日期:2020-08-10 |

| 圖書選購 |

| 型式 | 價格 | 供應商 | 所屬目錄 | $ 612 |

應用科學 |

$ 612 |

NatureScience & Mathy |

$ 612 |

科學科普 |

$ 632 |

中文書 |

$ 632 |

高等教育 |

$ 646 |

機械工程 |

$ 646 |

工程學群 |

$ 646 |

科學‧科普 |

|---|

| 圖書館借閱 |

| 國家圖書館 | 全國圖書書目資訊網 | 國立公共資訊圖書館 | 電子書服務平台 | MetaCat 跨館整合查詢 |

| 臺北市立圖書館 | 新北市立圖書館 | 基隆市公共圖書館 | 桃園市立圖書館 | 新竹縣公共圖書館 |

| 苗栗縣立圖書館 | 臺中市立圖書館 | 彰化縣公共圖書館 | 南投縣文化局 | 雲林縣公共圖書館 |

| 嘉義縣圖書館 | 臺南市立圖書館 | 高雄市立圖書館 | 屏東縣公共圖書館 | 宜蘭縣公共圖書館 |

| 花蓮縣文化局 | 臺東縣文化處 |

|

|

圖書介紹 - 資料來源:TAAZE 讀冊生活 評分:

圖書名稱:進階三軸銑削數控加工及實習

本書透過編程實例來直接導引三軸高速加工的應用概念,操作案例以Autodesk公司推出的PowerMILL®軟體做編寫,它是目前全世界廣泛應用於2~5軸數控銑削加工自動編程系統。該軟體具有易學易用、人員培訓快、程式製作時間縮短、機台加工時間縮短、加工表面品質提升、機台/刀具壽命延長與二次開發容易、方便經驗傳承等優勢特點。不僅可成為臺灣推動生產力4.0在數位製造上的利器,也讓學子們能夠更深一層的了解實務上的加工應用。

作者簡介:

吳世雄

現職

達康科技國際股份有限公司技術總監

學歷

臺北科技大學(專科二年制)

專長簡述

CAD/CAM產品設計/製造/檢測

五軸高階應用

逆向工程與創意產品設計

王敬期

現職

崑山科技大學機械工程系書記、兼任講師

學歷

崑山科技大學機械與能源工程研究所博士

專長簡述

機械加工實務

電腦輔助繪圖

熱傳與磨潤學

王松浩

現職

崑山科技大學機械工程系教授

學歷

美國匹茨堡大學機械工程學博士

專長簡述

電腦輔助設計/製造/工程分析

逆向工程/快速原型

機電整合

創意產品設計

目錄

推薦序

前言(Preface)

CH1 緒論(Introduction)

1.1 前言 2

1.2 CAD/CAM 軟體技術與數控工具機暨高速加工 2

1.3 結語 9

1.4 參考文獻(References) 9

CH2 基本加工概念與切削條件(Basic concepts in machining and machining conditions)

2.1 基本加工概念( Basic concepts) 12

2.2 切削條件(Machining conditions) 30

CH3 PowerMILL® 使用入門(Getting started with PowerMILL®)

3.1 簡介(Introduction) 46

3.2 啟動PowerMILL® 46

3.3 PowerMILL® 使用入門 50

CH4 2.5D 銑削與鑽孔加工(2.5D milli...

前言(Preface)

CH1 緒論(Introduction)

1.1 前言 2

1.2 CAD/CAM 軟體技術與數控工具機暨高速加工 2

1.3 結語 9

1.4 參考文獻(References) 9

CH2 基本加工概念與切削條件(Basic concepts in machining and machining conditions)

2.1 基本加工概念( Basic concepts) 12

2.2 切削條件(Machining conditions) 30

CH3 PowerMILL® 使用入門(Getting started with PowerMILL®)

3.1 簡介(Introduction) 46

3.2 啟動PowerMILL® 46

3.3 PowerMILL® 使用入門 50

CH4 2.5D 銑削與鑽孔加工(2.5D milli...

顯示全部內容

|

![塔木德:猶太人的致富聖經[修訂版]:1000多年來帶領猶太人快速累積財富的神祕經典 塔木德:猶太人的致富聖經[修訂版]:1000多年來帶領猶太人快速累積財富的神祕經典](https://media.taaze.tw/showLargeImage.html?sc=11100697818)